brass

our workshop works with brass which is a copper/zinc alloy. the brass is being cast in different methods – usually sand cast and lost wax technique. the cast is then ground, hand filed and worked to the desired form and finish in many steps. brass has a lively surface reacting to the climatical environment. following our long tradition of craft, we resist laquering our objects so they age naturally and patinate with time and use.

cast brass will always show a certain kind of „life“ – visible pores, little holes or even small inclusions. nevertheless, we work with the highest standard of craftmanship to maintain high gloss polished brass, as well as objects that combine polished and patinated brass surfaces. our patina is a kind of precious, artisanly applied rust i.e. intensified oxidation of the brass surface. usually salty and/or damp air, fingerprints and direct sunlight exposure enhance the natural patination/darkening process of polished brass surfaces.

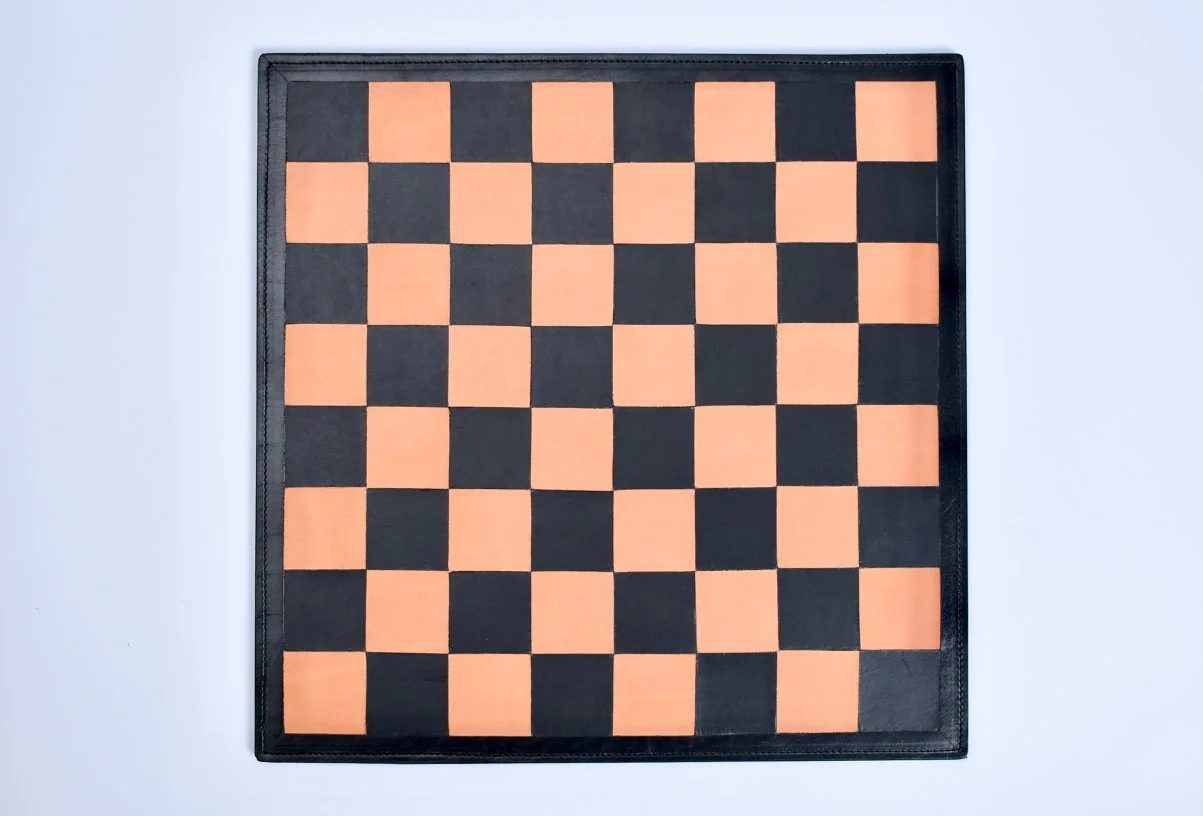

leather

we use vegetable-tanned leather with its origins in italy for our leather objects – this makes the magazine racks, bell straps, chess boards and all the other leather objects from our collection one of a kind.

the vegetable-tanned leather comes from the “conceria 800” tannery which is located in santa croce sull'arno in tuscany, italy. the tannery only uses raw materials from norway, denmark and switzerland. only vegetable extracts are used for tanning. the finish is made with beef tallow - it is therefore 100% natural. the leather is carefully selected to survive many decades and even become more beautiful with time.

horn

our horn material has its origins in cattle in central and south africa and is a by-product of the meat industry. the horn pieces are delivered in their whole form and pressed into flat slabs with great care and experience from many years of practice by our horn partners. the processing of horn takes a lot of care and time and requires a large number of work steps.

the hollow horn is sawn and sorted according to size. the hollows are placed in a hot oil bath and then heated over an open flame before being pressed into flat slabs. these slabs are then stored for at least three months so that the horn no longer warps and can be used for our purposes. horn comes in a large variety of colours and graining – every piece is unique.

wood

our collection also combines brass with wooden parts - in the floor mirror, the tripod tables, the cheese boards or the fireplace tool set, the use of wood creates a unique contrast of polished edges and warm wooden details. for this purpose, walnut and oak wood from certified european crop is processed with utmost care and expertise by our partners.

cane

wicker cane is a natural, robust and, above all, sustainable material made from the outer bark of the rattan palm, which grows mainly in the tropical regions of South East Asia.

it has a smooth, shiny upper surface; leaf projections, known as nodes, can be seen at regular intervals running across the fibers. the gloss is due to a layer of silicic acid (silicon dioxide). this is a kind of impregnation and slowly darkens the cane.

precision machines cut the material into narrow, extremely robust strips of varying thickness.

the soft interior, i.e. the pith of the rattan palm, is also cut into different thicknesses and used as cane (as used for the vice versa lamps), which is flexible and light as a feather and can be laid around very tight bends.

rattan palms are a very sustainable raw material: they grow quickly and can be harvested after just two years; after five to seven years, the plant has completely regenerated.